https://archive.triblive.com/business/local-stories/approval-nears-for-ati-venture-with-chinese-company/

Approval nears for ATI venture with Chinese company

Allegheny Technologies Inc.

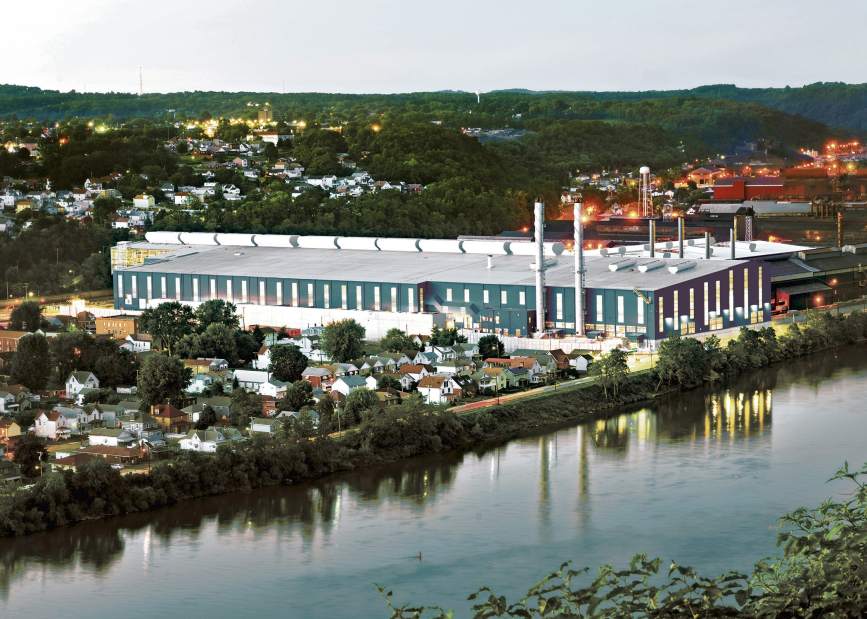

Allegheny Technologies Inc.'s Hot-Rolling and Processing Facility in Harrison.

Allegheny Technologies Inc. is preparing to start its joint venture with a Chinese stainless steel producer that will produce 60-inch-wide stainless steel sheets and create 100 manufacturing jobs in Western Pennsylvania.

The downtown Pittsburgh-based specialty metals company announced the venture with Yongqing LLC, an affiliate of Tsingshan Group, in November.

Tsingshan is the world's largest stainless steel producer.

ATI officials said the venture, Allegheny & Tsingshan Stainless, was awaiting one last regulatory and anti-trust clearance from an unspecified Asian country early this year.

“We're still awaiting final regulatory clearance here, which we expect in the next few weeks, and should be able to close during the first quarter,” Robert Wetherbee, executive vice president of ATI's Flat Rolled Products Group, said during a Jan. 23 earnings conference call.

“We see the first half of the year being the ramp-up period and expect to start seeing benefit in the second half of 2018, both in the utilization of the HRPF (Hot Rolling and Processing Facility) as well as the manufacturing and sale of product through the joint venture,” he said.

That clearance was still pending in early February, but ATI officials said they didn't expect any problems.

“We believe it's progressing normally, and we certainly expect it to be approved in the first half of the year, for sure,” said Scott Minder, vice president of investor relations for ATI.

In the conference call, Wetherbee said the initial startup of ATI's facilities and its activity with Tsingshan are “well under way.”

He said ATI has restarted the Direct Roll Anneal and Pickle (DRAP) line at its Midland facility and has initial metal in the market.

“(We are) getting very positive responses from our customers in terms of meeting their needs and the expectations from the quality perspective,” he said.

More capacity, rail traffic

Rail traffic is expected to increase with the joint venture, but by how much remains to be seen, Minder said.

Slabs will come to the Harrison facility by sea and rail from Tsingshan's $5 billion facility in Indonesia, where they will be hot-rolled into coils. The coils will be shipped by rail to the Midland facility, where they will be turned into the 60-inch-wide steel sheets.

The first shipments of the finished product will depend on the regulatory approval, Minder said.

“Once the regulatory approval is received and the joint venture is actually formed, we can start producing product very quickly,” Minder said.

Minder said no new jobs will be added at the hot rolling facility, which employs about 650 people. The 100 jobs are expected to be created at the Midland plant once the joint venture reaches full production.

Minder said the Harrison facility is underutilized, so it should be able to handle the additional volume with its current staff. The joint venture, however, will increase use at that site.

“The stated capacity of the joint venture is 270,000 to 280,000 tons of product,” he said. “When it gets to that level, the HRPF would be close to 50 percent utilized in its current configuration.”

The Harrison facility recently has been running at 30 percent capacity, he said.

United Steelworkers International Vice President Tom Conway, who chairs USW's ATI bargaining committee, said the union welcomes the restart of the Midland facility and the “return of a significant number of jobs.”

“We have reached an agreement with the company regarding the wages, staffing and working conditions under which the plant will operate,” Conway said. “While we would have preferred to have made the slabs to support this operation in Midland as well, we recognize the reality to the stainless markets, and that progress here can be incremental.”

Geographical advantage

John Tumazos, owner and CEO of Very Independent Research in New Jersey, said ATI will reap benefits from the joint venture, which will compete primarily with a Spanish-owned mill in Kentucky and a Finnish-owned mill in Alabama.

In addition to creating 100 jobs, ATI will charge the joint venture a fee to process the slabs at Harrison, then get half the profit from sales of the sheets that are finished at Midland, he said.

He said the Midland facility has an edge over its competitors because of its location and ATI's relationship with steel distributors. Competitors likely will lower their prices to stay viable, he said.

“I think there's a natural quadrant in the northeast of the country where Midland has a freight advantage,” he said. “(ATI) sells many specialty metals products. There might be sales relationships that (ATI) has that are stronger. There are steel distributors that were sad when (ATI) shut Midland because they lost a supplier and were asking (ATI) to reopen it.”

Madasyn Czebiniak is a Tribune-Review staff writer. Reach her at 724-226-4702, mczebiniak@tribweb.com or via Twitter @maddyczebstrib.

Copyright ©2025— Trib Total Media, LLC (TribLIVE.com)