Allegheny Technologies Inc.'s metal mill a cut above

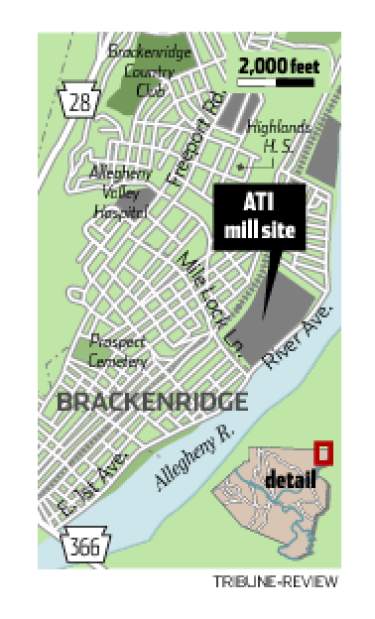

Allegheny Technologies Inc.'s new hot strip mill at its Brackenridge Works will be a powerhouse among specialty metal mills, company officials say.

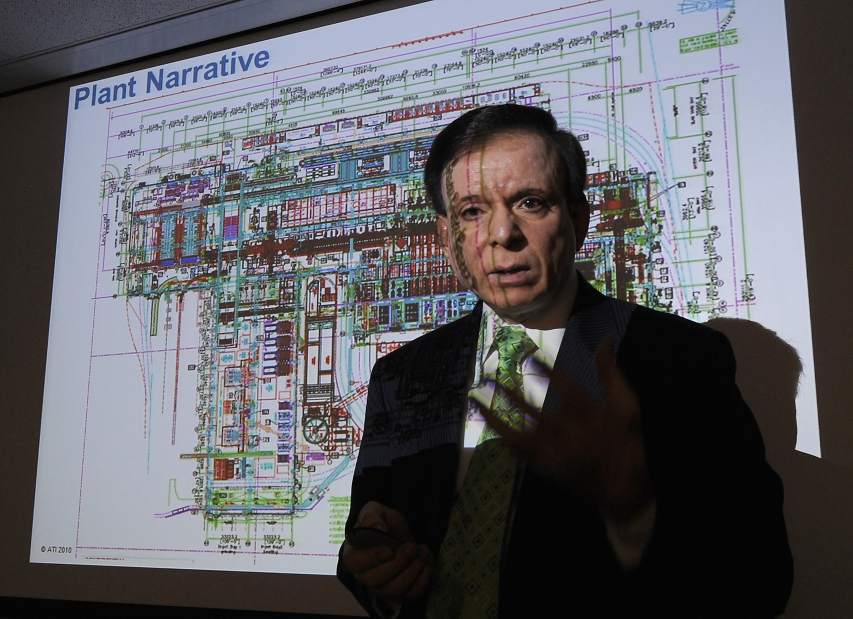

"There isn't a mill in the world that has as much combustion capability under one roof," Darin Sarin, the project manager, said of the Allegheny Ludlum unit's $1.1 billion, state-of-the-art facility. "This will be the most powerful rolling mill in the world."

Sarin, along with Allegheny Ludlum President Terry Dunlap and other Allegheny Ludlum officials, provided a tour on Thursday of the construction site for the mill officially known as the L. Patrick Hassey Hot Rolling Processing Facility.

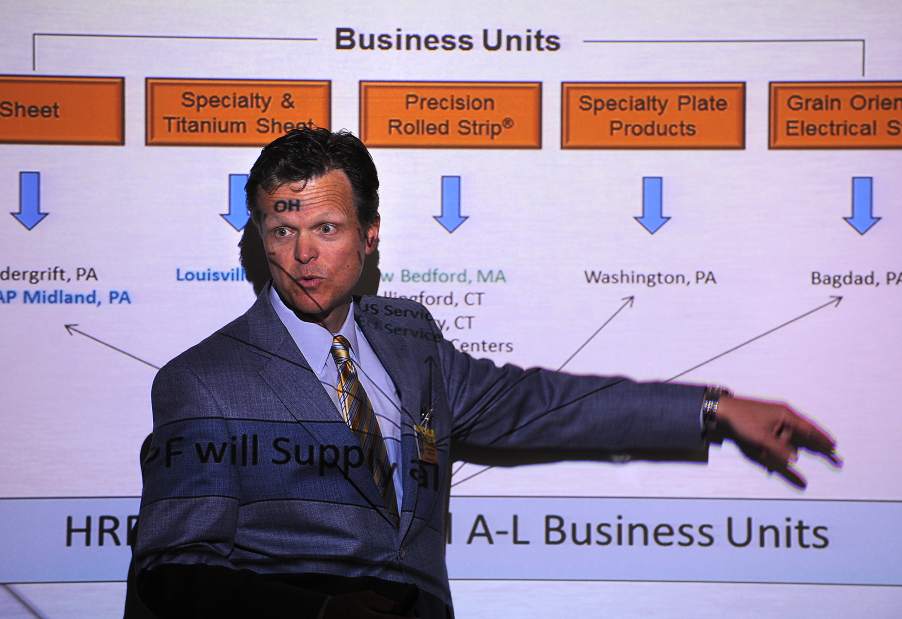

Sarin and Dunlap stressed that the mill, expected to open in December 2013, will be able to produce any type of specialty metal needed by manufacturers. ATI has evolved over the past decade from a traditional stainless steel maker to a company that also produces specialty metals such as titanium and nickel-based alloys for the aerospace, oil and gas, electric energy and medical device markets.

"We don't use the 'steel' word anymore," Dunlap said. "We're much more than that."

Sarin added that the plant will have abilities that competitors in the United States, and in some cases the world, have yet to see.

"This will be the only mill in the country that can produce a 2-meter-wide coil," he said.

The mill will be one of the world's fastest and most automated. "It used to take between 48 and 100 days from order to shipment," Sarin said. "Now, it will take between 14 and 48 days for the same process."

The most impressive part of the mill might be the space, or lack thereof, it takes up. The mill will be on 97 acres of land. By comparison, a similar mill recently built in Alabama by competitor ThyssenKrupp is on 1,200 acres.

"It's like building a skyscraper in Manhattan," Dunlap said.

Dunlap said ATI will process almost every piece of metal it produces through the Brackenridge Plant.

"This is the heart of the company," Dunlap said. "This has a very significant impact on the rest of ATI."

The current plant has come under fire in the past for large amounts of air and water pollution, but the new mill will have state-of-the-art air pollution control equipment, said Lauren McAndrews, the company's environmental relations representative.

Sarin added that the plant will continuously re-use water taken from the Allegheny River, thereby reducing what the plant needs to take from the river.

Less than 5 percent of the water used will be returned to the river.

"What does go back into the river will be cleaner than when it came in," he said.

More than 1,000 people work in the Brackenridge Works and the research and business center on Pacific Avenue in Harrison.

Dunlap said more than 35 percent of the company's revenue, which totaled $5.2 billion last year, comes from overseas buyers, and the company does its largest percent of sales, about 29 percent, from the chemical industry, such as oil and natural gas.

The construction work employs more than 600 workers and an additional 150 or so supervisors.